Hi, Welcome to JST!

Mobile/Wechat/Whatsapp: 0086 13609065180 Email: jstgz@jst-seals.com

Working Pressure: 0~30000Psi;

Working Temperature: -60℃~+260℃;

Sealing Material: modified PTFE, high performance PEEK, excellent corrosion resistant alloy component;

The product solution covers almost all current 6A gate valves.

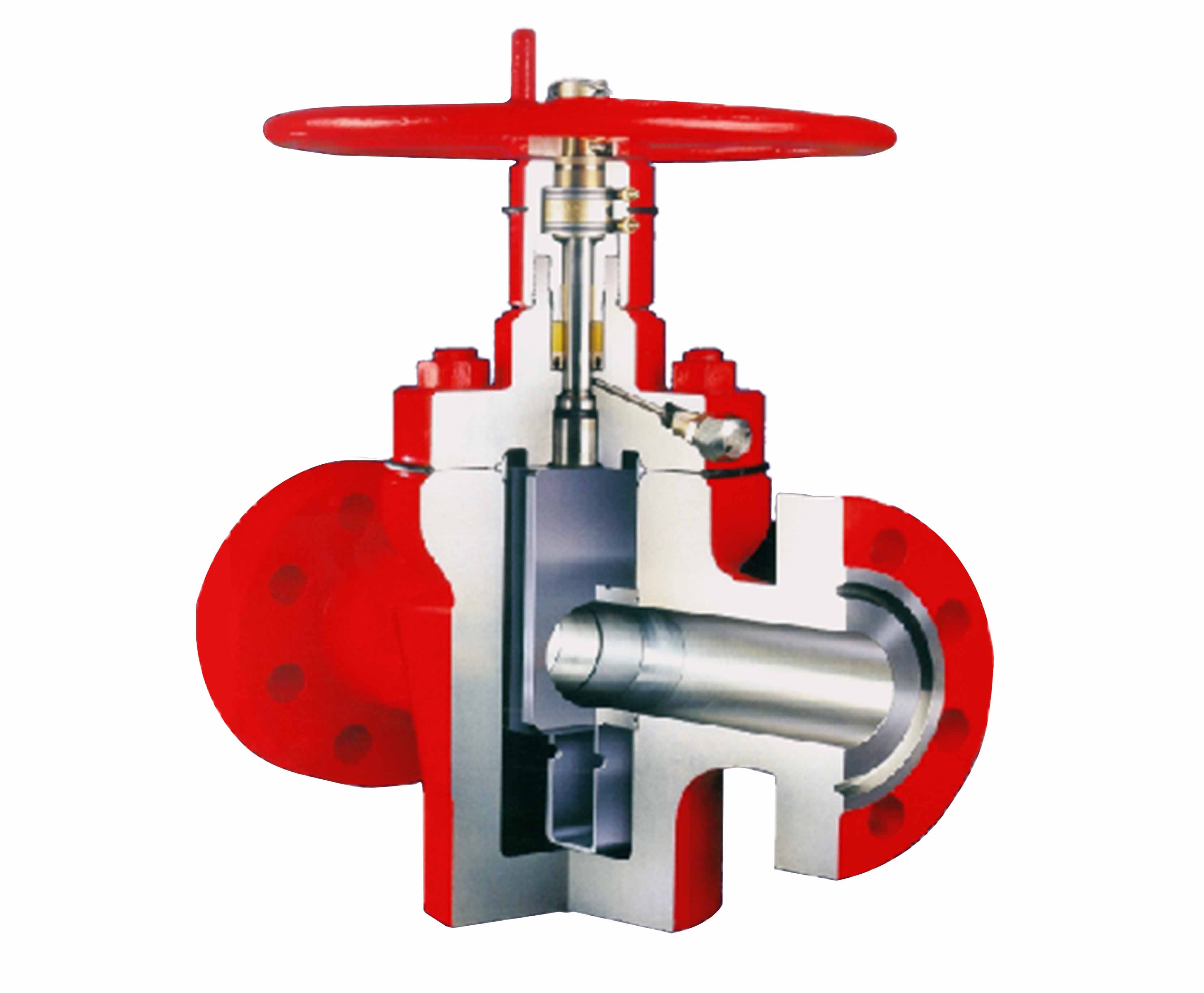

Due to its extremely harsh working conditions and the need for safety, the API 6A high pressure gate valve have high demands on the quality and stability of the valve stem seal assembly.

JST has a complete API 6A high pressure gate valve test equipment to conduct a large number of tests, and has rich experience for the customer's quality and safety escort.

Solution features: high pressure resistance, acid base resistance, fracturing fluid resistance;

Easy installation, simple groove, good stability;

Suitable for almost all the slab gate valves in oil fields;

We made very targeted adjustments to the materials to effectively improve the lifetime of the seals. In accordance with API Q1 requirements, all key materials have got the immersion certificates.

Description: select different materials according to different working conditions. If you have special requirements (pressure, temperature, speed, special chemical, etc., please contact us.

Hydraulic cylinder XTP hydraulic sealing solution

Working pressure: ≤60MPa;

Working temperature: -50℃~+210℃;

Working speed: ≤3m/s;

Medium: hydraulic oil, gas, etc.;

Sealing material: Modified PTFE, high performance rubber.

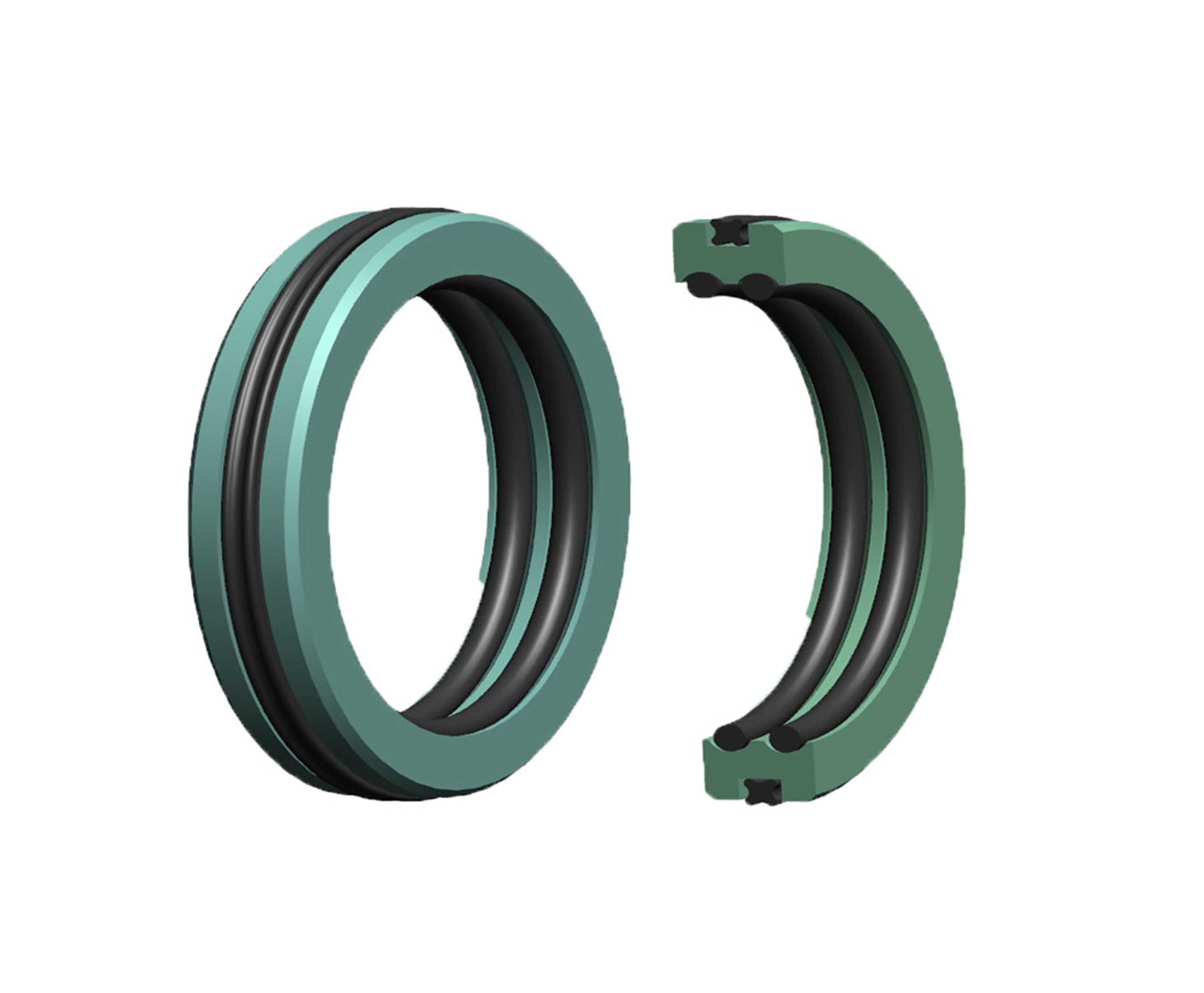

XTP combination seals, add X ring to the dynamic sealing surface, combined with the strength of the modified PTFE, can resist high pressure, have multiple sealing functions, can achieve to seal between two different chemicals; (such as gas and hydraulic oil). It can achieve low permeability for the chemical and the friction of the seal is very low. Therefore, the device operates at a lower power consumption and has a longer life.

Note: Select different materials according to different working conditions. If you have special requirements (pressure, temperature, speed, special chemicals, etc., please contact us.

Working pressure: ≤35MPa;

Working temperature: -55 ° C ~ +250 ° C;

Working speed: ≤15m/s;

Chemical: various chemical or corrosive environment;

Sealing material: high performance engineering plastics;

Function: shaft seal;

Dimension: shaft diameter ≥ 1.5mm ;

Features: excellent wear resistance, high and low temperature resistance, can prevent glue erosion;

Application: pumps, valves, joints.

Note: Select different materials according to different working conditions. If you have special requirements (pressure, temperature, speed, special chemical, etc., please contact us.

Provide customized technical service for specific sealing solutions for all specialized rubber products

Customized technical services can be provided for all specialized rubber and plastic products

For more details, please contact our customer service, welcome your inquiry and guidance.